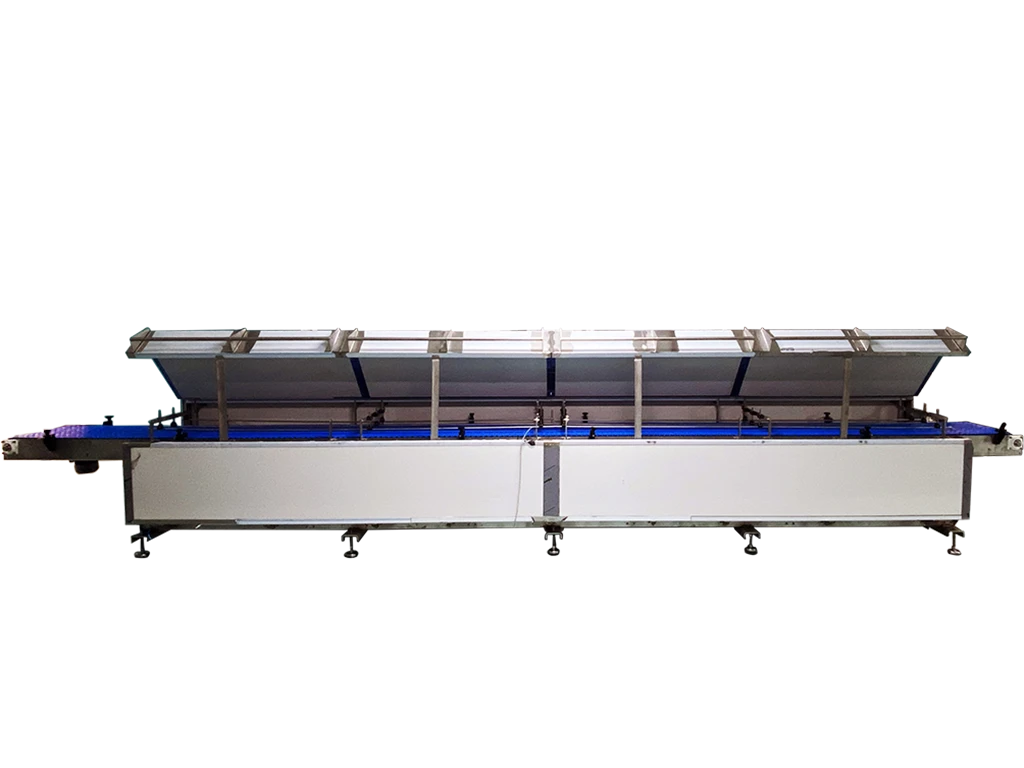

Cooling Tunnel

SNL - COOLING 100Our high-efficiency cooling tunnel allows cooling of various food products such as pastry products, biscuits, cakes, tablets, bar chocolates, croquants and completing the production process of the products by taking their final shape.

Our Cooling Tunnel is connected to the Glycoli cooling liquid line and the tunnel is cooled by heat exchangers and fans located under the conveyors along the tunnel.

The high insulation, modular belt system and fan cooling system in our cooling air tunnel can also cool packaged products. We can change the machine length and make revisions for the desired production capacities.

+ Top covers can be opened, so access to every point of the cooling tunnel is possible.

+ Covers, side barriers and base of the Cooling Tunnel are insulated with high density polyurethane, thus providing high efficiency.+ Speed of the conveyor belt and fans can be adjusted by the driver.

+ It has modular conveyor belts, thus cooling the product quickly and at high capacity.

+ Temperature can be reduced up to 0.1 degrees.

+ Side panels are modular and removable, thus cleaning and maintenance are easy.

+ Fan and Heat Exchanger systems are skid-mounted, thus easy to maintain and clean.

+ Cooling System; Heat Exchanger and Fan Blowing

+ All areas of the machine are made of 304 ASIS Stainless Material; * Covers, Base, Side Body and Chassis

+ Band systems and parts used are completely suitable for food.

+ Speed Control Drivers

+ PLC Touch Screen and Control Panel

+ Emergency Buttons

+ Electricity; 4kW | Three-phase+ Dimensions; Height 1 mt | Width: 1m | Length: 7.50 mt | Weight: 420 Kg

Cooling Tunnel Features

Cooling tunnel working video

About Cooling Tunnel

The area of use of Cooling Tunnels is the food sector; It is very useful for pastry products, cakes, biscuits etc. The most intensive area of use is chocolate products; tablet chocolate, bar chocolate, decorated or filled chocolate products, packaged chocolates etc. or croquants